Browsing the World of Fasteners and Machining: Approaches for Accuracy and Rate

In the elaborate realm of fasteners and machining, the mission for precision and speed is a continuous obstacle that requires careful attention to information and calculated preparation. From recognizing the varied variety of bolt types to choosing optimal materials that can hold up against rigorous demands, each step in the process plays an essential role in attaining the wanted outcome.

Understanding Fastener Kind

When picking fasteners for a task, understanding the different kinds offered is important for ensuring ideal efficiency and dependability. Bolts are utilized with nuts to hold materials together, while screws are flexible bolts that can be made use of with or without a nut, depending on the application. Washers are important for distributing the tons of the fastener and stopping damages to the material being attached.

Choosing the Right Products

Understanding the importance of selecting the ideal materials is critical in making sure the optimal performance and dependability of the picked bolt kinds reviewed previously. When it concerns bolts and machining applications, the product option plays a crucial role in identifying the total stamina, resilience, rust resistance, and compatibility with the desired setting. Various products supply varying residential properties that can substantially impact the efficiency of the bolts.

Common materials utilized for bolts include steel, stainless-steel, brass, titanium, and aluminum, each having its unique toughness and weaknesses. Steel is renowned for its high toughness and sturdiness, making it ideal for a variety of applications. Stainless steel uses superb rust resistance, perfect for environments susceptible to moisture and chemicals. Light weight aluminum is light-weight and corrosion-resistant, making it appropriate for applications where weight decrease is important. Brass is often chosen for its visual allure and excellent conductivity. Titanium is recognized for its phenomenal strength-to-weight proportion, making it ideal for high-performance applications. Choosing the ideal product entails taking into consideration aspects such as stamina demands, ecological problems, and budget restrictions to guarantee the desired performance and durability of the bolts.

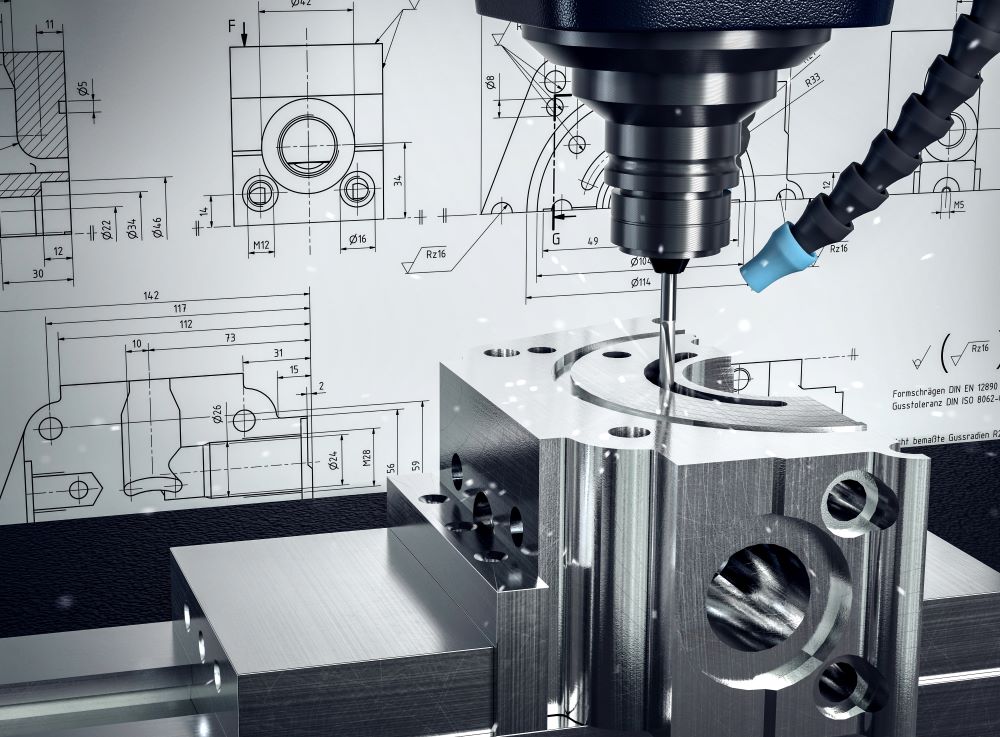

Accuracy Machining Techniques

Along with CNC machining, other accuracy methods like grinding, turning, milling, and exploration play crucial functions in bolt manufacturing. Grinding aids attain great surface area coatings and tight dimensional tolerances, while transforming is frequently made use of to create round elements with exact sizes. Milling and boring procedures are crucial for forming and developing holes in fasteners, guaranteeing they fulfill specific specs and function appropriately.

Enhancing Rate and Efficiency

To optimize fastener manufacturing procedures, it is essential to enhance procedures and execute reliable techniques that match accuracy machining methods. One key method for enhancing speed and performance is the implementation of lean manufacturing concepts. By minimizing waste and concentrating on continual renovation, lean practices assist get rid of bottlenecks and optimize operations. Additionally, buying automation innovations can dramatically enhance production rate. Automated systems can take care of recurring jobs with precision and speed, allowing workers to concentrate try this on more facility and value-added tasks. Taking On Just-In-Time (JIT) supply management can also boost efficiency by making certain that the ideal materials are available at the correct time, minimizing excess supply and lowering lead times. Promoting a society of partnership and interaction among team participants can improve total performance by advertising openness, analytic, and development. By incorporating these approaches, producers can attain an equilibrium between rate and precision, ultimately boosting their one-upmanship in the fastener sector.

Quality Control Measures

Implementing extensive quality control steps is vital in ensuring the reliability and consistency of fastener read this post here items in the manufacturing process. Quality control measures encompass various phases, starting from the choice of resources to the last examination of the completed fasteners. One fundamental aspect of top quality control is carrying out comprehensive material evaluations to validate conformity with specs. This entails evaluating aspects such as product durability, structure, and strength to ensure that the fasteners satisfy market criteria. In addition, keeping an eye on the machining refines is important to promote dimensional accuracy and surface area coating top quality. Using advanced modern technology, such as automatic examination systems and accuracy measuring tools, can improve the precision and efficiency of quality control treatments.

Routine calibration of tools and equipment is essential to preserve uniformity in production and make certain that bolts meet the required tolerances. Implementing stringent protocols for recognizing and addressing non-conformities or flaws is vital in preventing substandard items from entering the marketplace. By developing a detailed top quality control framework, manufacturers can promote the credibility of their brand and deliver fasteners that fulfill the highest possible criteria of efficiency and longevity.

Verdict

In the intricate realm of bolts and machining, the quest for accuracy and speed is a continuous challenge that demands meticulous attention to detail and strategic planning. When it comes to fasteners and machining applications, the product choice plays an essential duty in establishing the overall strength, longevity, rust resistance, and compatibility with the desired setting. Precision machining includes numerous advanced approaches that make certain the limited resistances and specs needed for bolts.In addition to CNC machining, various other accuracy techniques like grinding, transforming, milling, and boring play crucial functions in fastener manufacturing.To enhance bolt manufacturing processes, it is essential to improve procedures and apply effective approaches that complement accuracy machining techniques.